Windows Central Verdict

Whilst the Ender 5 S1 is good, its $560 price tag hampers its appeal, and dubious speed claims do not help it either.

Pros

- +

Box frame printers are very space efficient

- +

Sprite high-flow hot-end and extruder are very capable

- +

Easy to understand and operate screen interface

- +

Very easy assembly

Cons

- -

250mm/s and 2000mm/s2 acceleration claims fall flat

- -

Lots of friction in the feeding tube

- -

Optional enclosure panels are practically useless

- -

The bed doesn’t stay consistently trammed

Why you can trust Windows Central

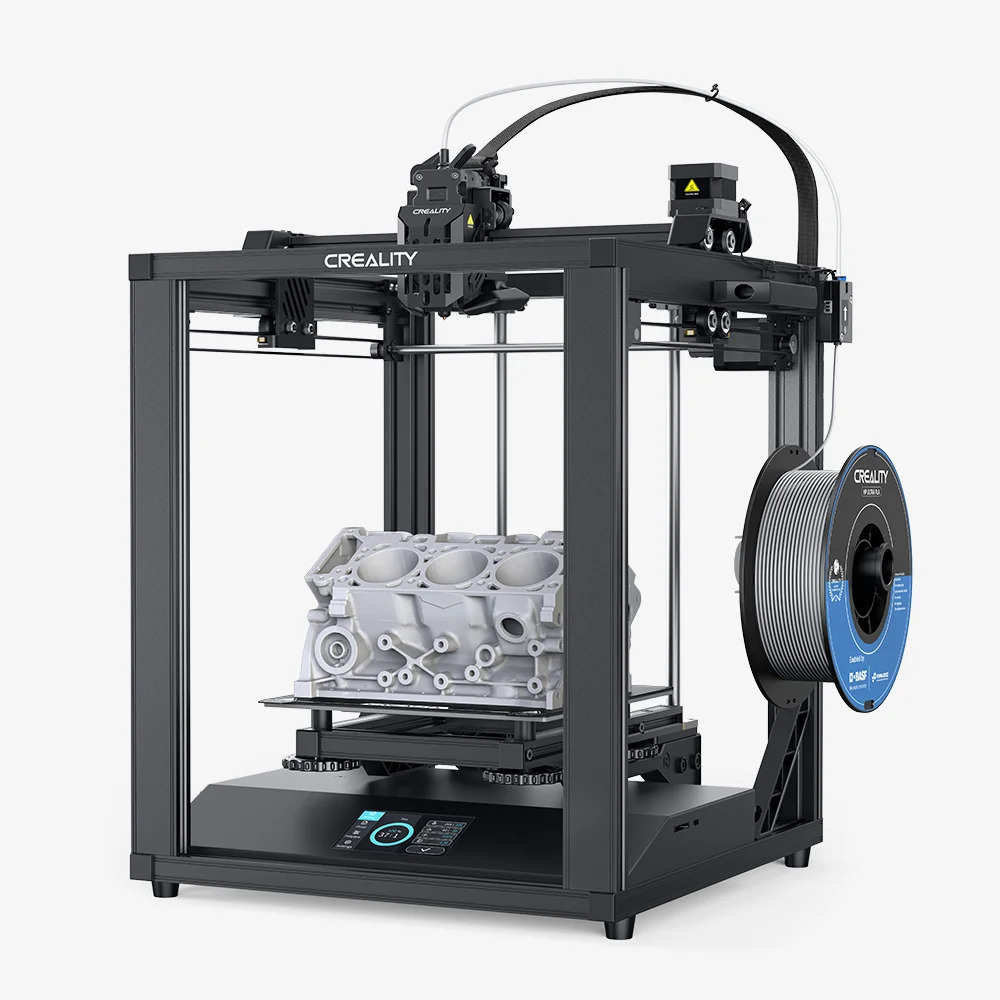

Creality has been in the home 3D printer market for a while; with their near stratospheric rise to fame with the CR-10 and later the Ender 3, Creality went on to swap the “i3” style design for a box frame cartesian and bring out the Ender 5. What is a Box frame cartesian? Well, unlike a CoreXY such as my Voron v0.1 or the Creality Ender 7, wherein two motors work together to move in the X and Y directions, a box frame cartesian works more like the Ender 3 with discrete motors for X, Y, and Z all working independently of each other, the upside of this is that it is incredibly easy to make, the downside is that because it is one motor per axis, top speed, and acceleration isn’t quite as high.

That's what the Ender 5 was, and the Ender 5 S1 is that, but using the Ender 3 S1 as a stepping stone, so instead of the 12864 full graphics LCD, we have a full-color touchscreen; instead of the PTFE lined MK8 hotend and a cheap plastic bowden extruder, we have an all metal higher flow hotend with a dual gear direct sprite hotend.

We have a CR-Touch automatic bed probe and a spring steel magnetic bed instead of the floppy fridge magnet-style one. This is based on the Ender 3 S1, which means it has a similar build volume of 220x220x280. While looking at it next to something like the Elegoo Neptune 3 Pro with the same build volume, this appears larger. Once you account for the fact that aside from the filament spool on the side, the Ender 5 S1 is fully encased, it requires less room on the desk than a bed slinger that needs clearance on the front and the rear for the bed, and room for the filament, either on the top or on the side.

Creality Ender 5 S1: Price, availability, and specs

The Ender 5 S1 is currently available from the Creality website for $500, but the normal retail price is $560. I also found the Ender 5 S1 available on Amazon US for $599 if you prefer an easy returns policy.

As is common when buying directly from the OEM, you can add other items easily to your basket, including Creality filaments like their CR-PLA Matte or their new HP-Ultra PLA developed in partnership with materials giant BASF. You can also get spare nozzles, extruders, and other consumables for reasonable prices.

| Specs | Creality Ender 5 S1 |

|---|---|

| Build volume | 220mm x 220mm x 280mm |

| Print Surface | Spring steel plate, PC sticker for adhesion |

| Extruder | 3.5:1 gear ratio, Dual drive gears |

| Nozzle | 0.4mm MK-HF nozzle, +1 spare in box |

| Interface | 4" colour touch screen, USB-C, Full sized SD |

| Accessories | Filament sensor, CR-Touch |

Creality Ender 5 S1: What you'll like

There is a lot to like about the Ender 5 S1, it’s a pretty design that’s very sleek, and the entire printer, aside from the spool holder, is inside of the cube, making it much easier to enclose for higher temperature filaments, but also easier to pack multiple machines into a space, you no longer need to account for the bed travel as well as the potential spool width. The only thing about the footprint that I dislike is the power cable comes out the side near the front, but they do not supply a 90-degree cable; a small nitpick, but annoying if you have limited width available.

It takes about 20 minutes to set up the Ender 5 S1. For the base, Z axis, and XY gantry and fully assembled sub-components, all you have to do are attach the four vertical beams to the base with two screws per beam, then attach the XY gantry on top with two more screws per beam. Lastly, you need to attach the print bed to the Z axis, as well as the bed supports with four screws, and slide that into the frame. The wiring is plug and play; they are all labeled and hard to plug into the wrong places as the lengths of the wires are terminated to make it as simple as possible; Creality also has a rather detailed and useful manual.

All the latest news, reviews, and guides for Windows and Xbox diehards.

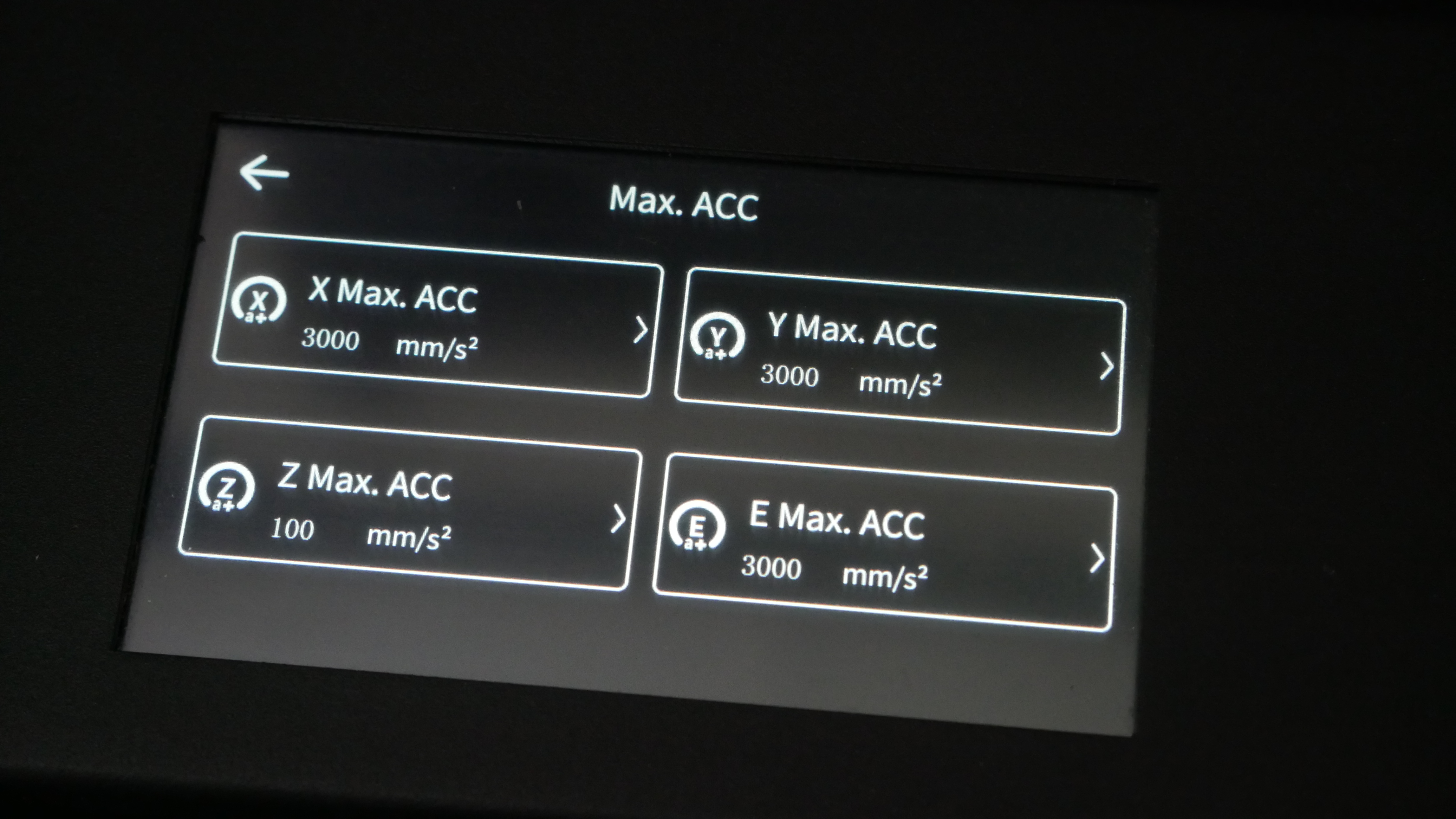

Once you're all up and running, you turn it on and get to see the 4” color touchscreen, and this is something I’ve grown to appreciate, Mostly because it is landscape. Most of the 3D printers I own with touchscreens are portrait or tiny; the size of the screen here, along with nice finger-sized buttons (even for chubby fingers), works well and is intuitive enough, allowing you to have temperature presets, manually adjust temperature and jog movement, you can even change printer parameters such as speed, maximum accelerations, and jerk, all without having to connect the printer to a serial host.

Next is something that Creality has historically suffered with, and that would be the hot end and extruder. On the Ender 5 S1, we have the Sprite extruder, as seen on the Ender 3 S1. Still, instead of a standard direct drive like we saw there with the short filament path and stubby heatsink, the Ender 5 S1 has a short piece of PTFE tubing leading to a hotend that looks remarkably reminiscent of the one found in the Ender 7, including a thicker heater block and mildly longer nozzle for increased flow for printing at those increased speeds.

This isn’t what I was expecting; I truly expected the short filament path fully integrated Sprite Pro. However, this design does have some advantages, including easier maintenance and more widely available parts in case things go wrong. It also allows you to swap out the hotend whilst keeping the extruder the same; for example, I could swap in a Revo-CR from E3D if I could find somewhere to mount the fan, and that would give me access to the quick swap E3D Revo ecosystem, something I’m a big fan of.

Creality Ender 5 S1: What you won't like

For everything there is to like, there are more than a few foibles here, starting with the projected speed. Creality happily proclaims the Ender 5 S1 can reach speeds of 250mm/s on their website with 2000mm/s2 accelerations. However, those are kinds of fibs. Yes, the Ender 5 S1 can print at that speed, but those speeds aren't the printing speeds. In the included Creality slicer, the 250mm/s speeds are only for the travel moves, as in non-printing moves, and in one profile, the infill. Now, this isn't the end of the world, I can manually adjust the Ender 5 S1 to print at higher speeds, but that incurs other issues, such as ringing from the rather weighty tool head.

The other issue is that, at least, my unit didn’t come with the advertised 2000mm/s2 accelerations; this is quite easy to see through the built-in screen, but also hooking it up to a computer and reading the serial interface. What is worse, though, is that when the accelerations were increased to the advertised ones, ringing got even worse, even at lower speeds than stock. I’m not really a “Klipper all the things” type of 3D printer owner, but if any recent printer benefited from Klipper and the resonance compensation “input shaping” feature, it would be this machine, one proudly claiming high speeds everywhere. What’s even more annoying is that the Ender 5 S1, even when put to the specs, it says it has, is often out printed by my other printers, including the Elegoo Neptune 3 Pro right next to it, a standard bed flinger i3 with no speed claims to its name.

I have spoken with Creality and peers with the same machine, and this appears to be an isolated issue in my unit. Everyone else I have spoken to has had the expected 2000mm/s2 acceleration or even 3000mm/s2 acceleration.

Another issue potentially with my unit is that the feeder tube, sometimes referred to as a “reverse bowden,” that guides the filament from the filament runout sensor to the hotend, has a lot of friction, not just so that feeding was an issue (It was, especially with softer TPUs). Still, when the extruder was pulling filament through off of the spool holder, you could see, and often here, it was struggling; this is also compounded when I removed the tube from the printer and blew through it, a lot of ground filament dust was inside. I personally buy the PTFE tubing with a larger internal diameter, but this feels like something that shouldn't have fallen through the cracks.

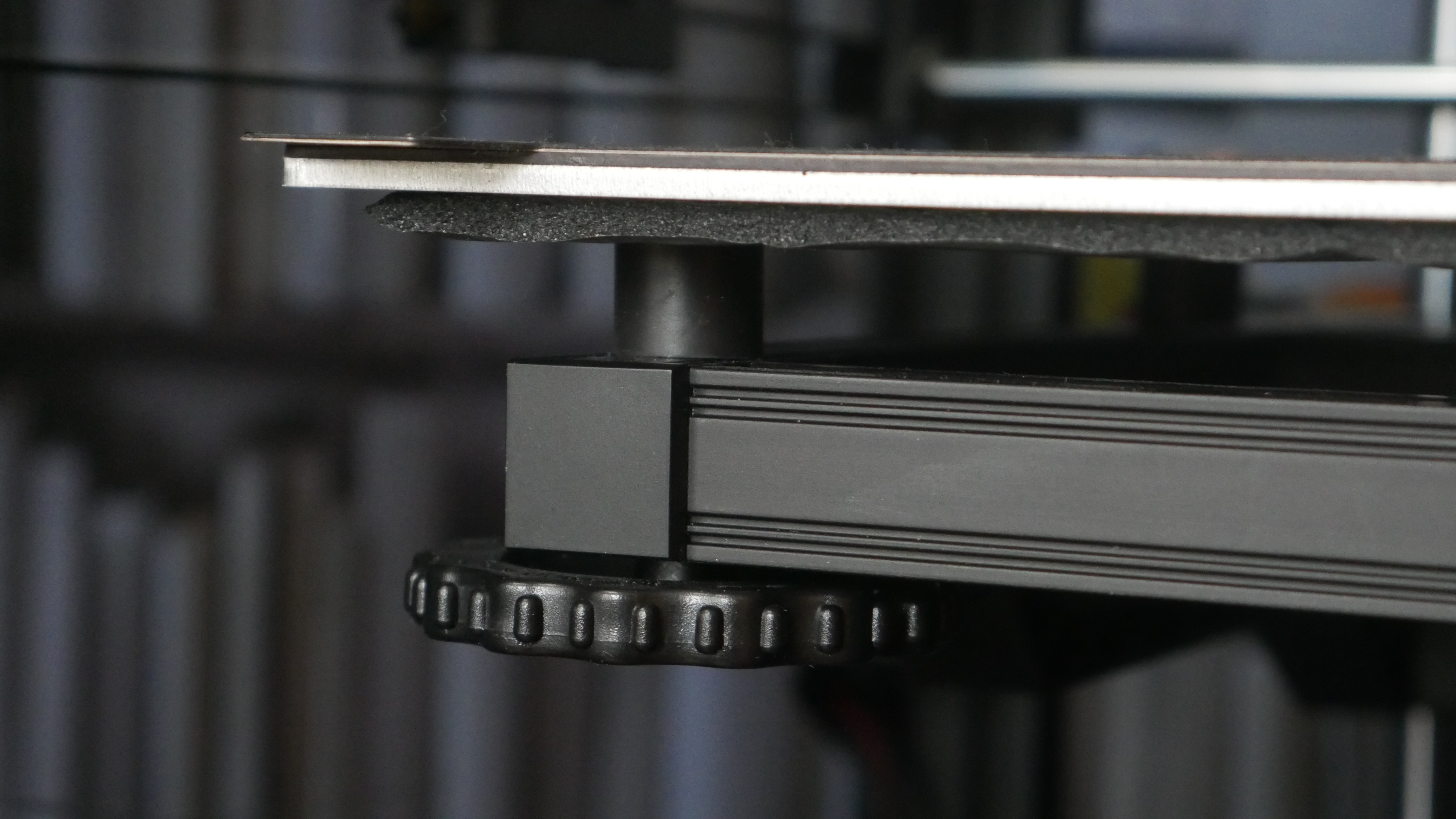

Lastly, in a similar issue that I had with the Sovol SV04, the Ender 5 S1 has a CR-touch, a bed probe that creates a grid (called a mesh) of the bed and uses software trickery to make that potentially uneven bed flat for the first layer. However, like Sovol, Creality chose to still include manually tramming springs and wheels in each corner, meaning that the official way to have a “perfect” bed is to adjust the Z-offset, do manual leveling with the wheels, and then do the mesh probe. The second step should not be there. You are already compensating for an uneven bed, a statically mounted bed would be easier for the end user and much less likely to drift over time, as mine is. Yes, the vibrations of this printer in use are causing my bed to not stay trammed to the gantry. The point of bed probes is to make the first layer as “set and forget” as possible, but if I have to watch the first layer like a hawk to see if the level has changed in one or more of the corners, what is the point?

The bonus niggle is the optional enclosure. I was delighted when Creality said there was an enclosure for the Ender 5 S1 and asked them to send it over, but it seems only about 90% complete, as there is no top part, and may I remind you that enclosures are for keeping the heat in and drafts out, but heat rises. Not only that, but the print starts at the top of the bed, closer to the cooler ambient air. If this is remedied with a top hat of some sort, maybe I could tell people to consider it, but the current state of the enclosure is a no-go for me.

Creality Ender 5 S1: Competition

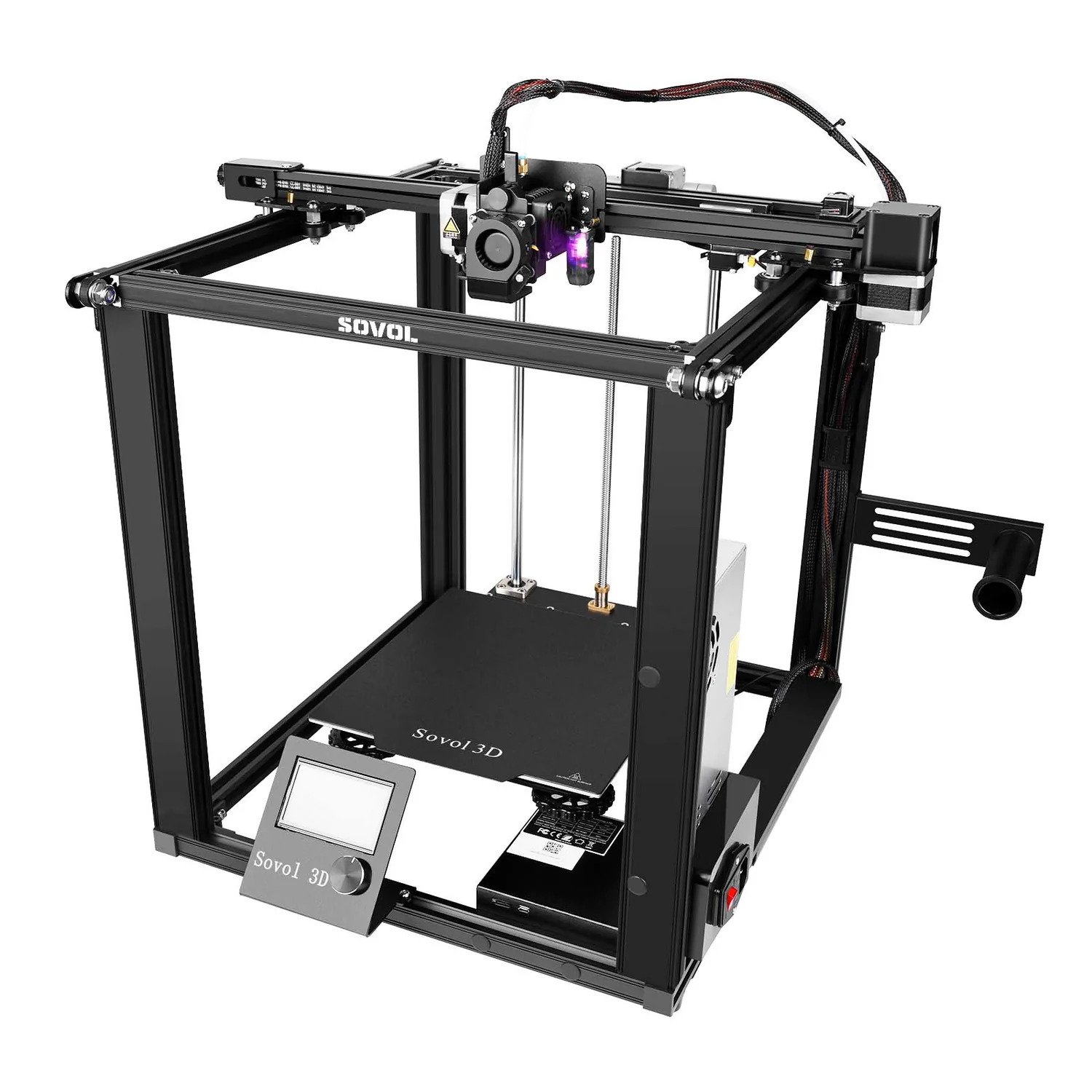

Believe it or not, there are a few box frame cartesian 3D printers, including the Sovol SV05, the Elegoo Neptune X, and even the older Ender 5 and Ender 5 Plus. The problem Creality finds itself in here is that they are significantly more expensive than the other options without much more to offer.

Take the Elegoo Neptune X; it is usually $400 but can be had for $309 currently. It has a 220x220x300mm build volume making it slightly taller than this. However, it doesn't have a direct drive extruder, a high-flow hot end, or automatic bed leveling. The Sovol SV05 is another competitor, usually going for $349 but currently available for $299. The SV05 does have a direct drive extruder, a CR-touch automatic bed probe, and a 220x220x300mm build volume; the only perceived downside over the others would be the use of an old-school 12864 full graphic monochrome display.

Lastly, we have Creality’s biggest competition: Creality. The original Ender 5 and Ender 5 Plus are still well-respected printers, and for the same $560 as the Ender 5 S1, you can have the Ender 5 Plus, with a gargantuan 350x350x400mm build volume, a print bed that is supported on both sides, not just the rear like here, a BL-Touch bed probe, and, most importantly of all I think years of software support and 3rd party upgrades.

It is not that the Ender 5 S1 is a bad printer; on the contrary, I have many wonderful prints out of it. However, there is stiff competition here, and the Ender 5 S1 just feels too safe for the price point.

Creality Ender 5 S1: Should you buy it?

You should buy it if:

- You like box frame cartesian printers

- You're already in the Creality ecosystem

- You need more height than current i3 printers give you.

You shouldn't buy it if:

- You are budget conscious

- You want to print fast out of the box

- Want a fully enclosed printer

I’ve had an interesting time reviewing the Ender 5 S1 from Creality, it isn't my first box frame printer, and I'm sure it won't be my last, but I think this is the first time I’ve been somewhat disappointed in a printer that I genuinely wanted to be great. This is my first taller printer in this form factor, but I forgot that it comes at the cost of longer heat-up times and a worse thermal envelope. I was fully expecting the noise from the fans to be loud when printing fast, but the vibrations of the frame, as well as specifically the Y axis, being loud threw me off. I wanted the enclosure to be good but without a top, it is an acrylic door with some side panels, and those panels also vibrate when trying to push the printer to its limits.

I’m told the Ender 5 S1 is compatible with the Creality Sonic Pad, a 7” tablet that allows a user to quickly and easily install Klipper onto their printers to get faster speeds and better quality, all while gaining an even better touchscreen experience and a web interface for sending the files to, however, the Ender 5 S1 doesn't come with Klipper or a Sonic Pad. The Ender 5 S1 feels like it’s 85% done, just a little longer left in the oven, and this could have been one of the best 3D printers. Perhaps an Ender 5 S1 Pro in the future, but until then, this is what we have, for better or for worse.

Domenico is a Former Contributor for Windows Central, covering 3D printers and their essential accessories.