Consumerization of 3D Printing: Windows 8.1 drivers and a Windows Phone app

All the latest news, reviews, and guides for Windows and Xbox diehards.

You are now subscribed

Your newsletter sign-up was successful

One of the many technology trends that we are looking forward to in 2014 is the consumerization of 3D printing, especially after Windows 8.1 introduced native 3D printing support last year. The first industry event of the year, CES 2014, reflected the excitement in the category with new 3D printers and new apps.

At the event, 3D printer manufacturer Beijing TierTime launched their Windows 8.1 3D printer driver to the world. Now owners of the TierTime Up Plus 2 and the affordable TierTime Up Mini 3D printers can experience the full benefits of 3D printing support on Windows 8.1.

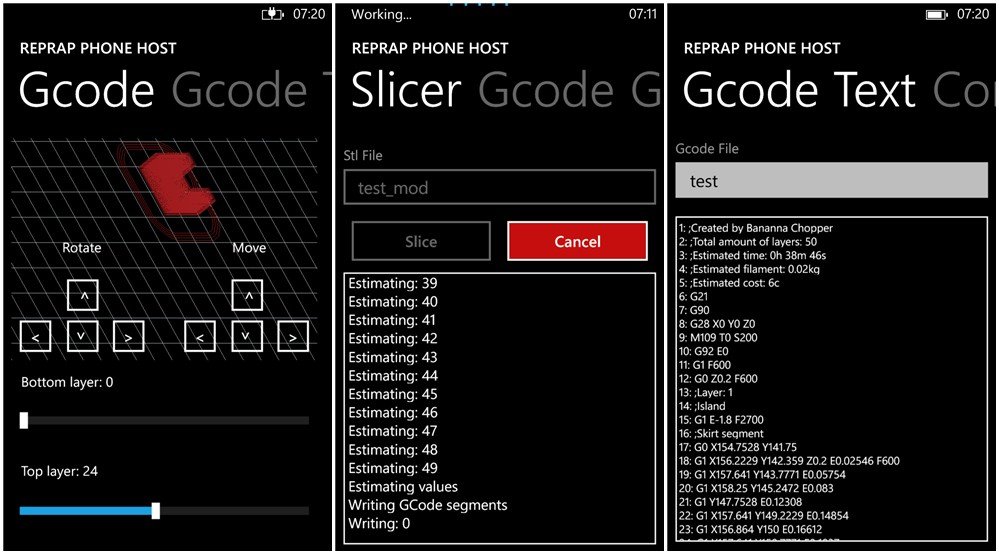

Far from the technology glitz in Las Vegas, two 15 year old students in South Africa launched an interesting 3D printing app. RepRap Phone Host is a Windows Phone 8 app that allows you to process and then ultimately 3D print STL format 3D models on your RepRap-type 3D printer with ’firmware.

To get the app up and running, all you need is to add a Bluetooth serial bridge to your 3D printer, pair with it in the Bluetooth menu, and then just select it from the drop down menu inside the app to connect. The developer has also volunteered to help set things up for less seasoned users, and you can drop a mail to gerhard@bananna3d.com to connect.

The duo claims that their app is the first mobile application ever to allow users to print directly from a 3D (STL) model instead of a toolpath (GCode– Bananna which processes the model into a toolpath.

The app includes the ability to print models on a RepRap-type 3D printer over a Bluetooth connection as well as the ability to render STL and GCode files. The app allows opening STL and Gcode files from email et al, and uploading files to your SkyDrive.

If you indulge in 3D printing, download RepRap Phone Host for free from the Windows Phone Store, and let us know how it works for you. Check out www.bananna3d.com for more details about their project.

All the latest news, reviews, and guides for Windows and Xbox diehards.

Abhishek is a Former Contributor for Windows Central, covering Windows Phone and more.