The LulzBot TAZ Workhorse is the company's powerhouse. Designed for continuous printing in business conditions, the TAZ Workhorse is built from the ground up to be reliable and sturdy. Made wholly in the USA, the Workhorse is a mix of 3D-printed parts and a sturdy aluminum framework. At the same time, the belt-driven X-axis adds an extra layer of reliability to every print.

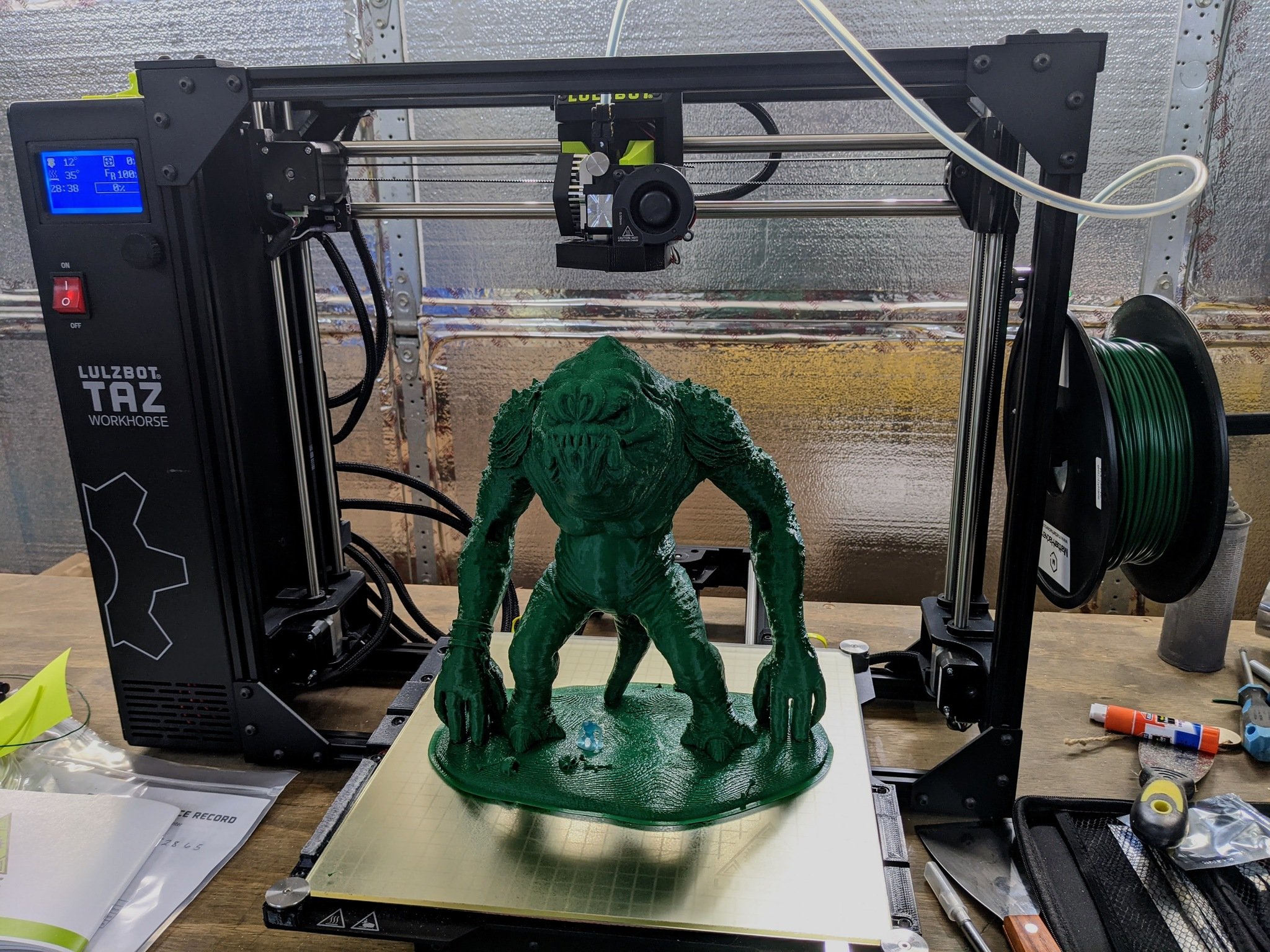

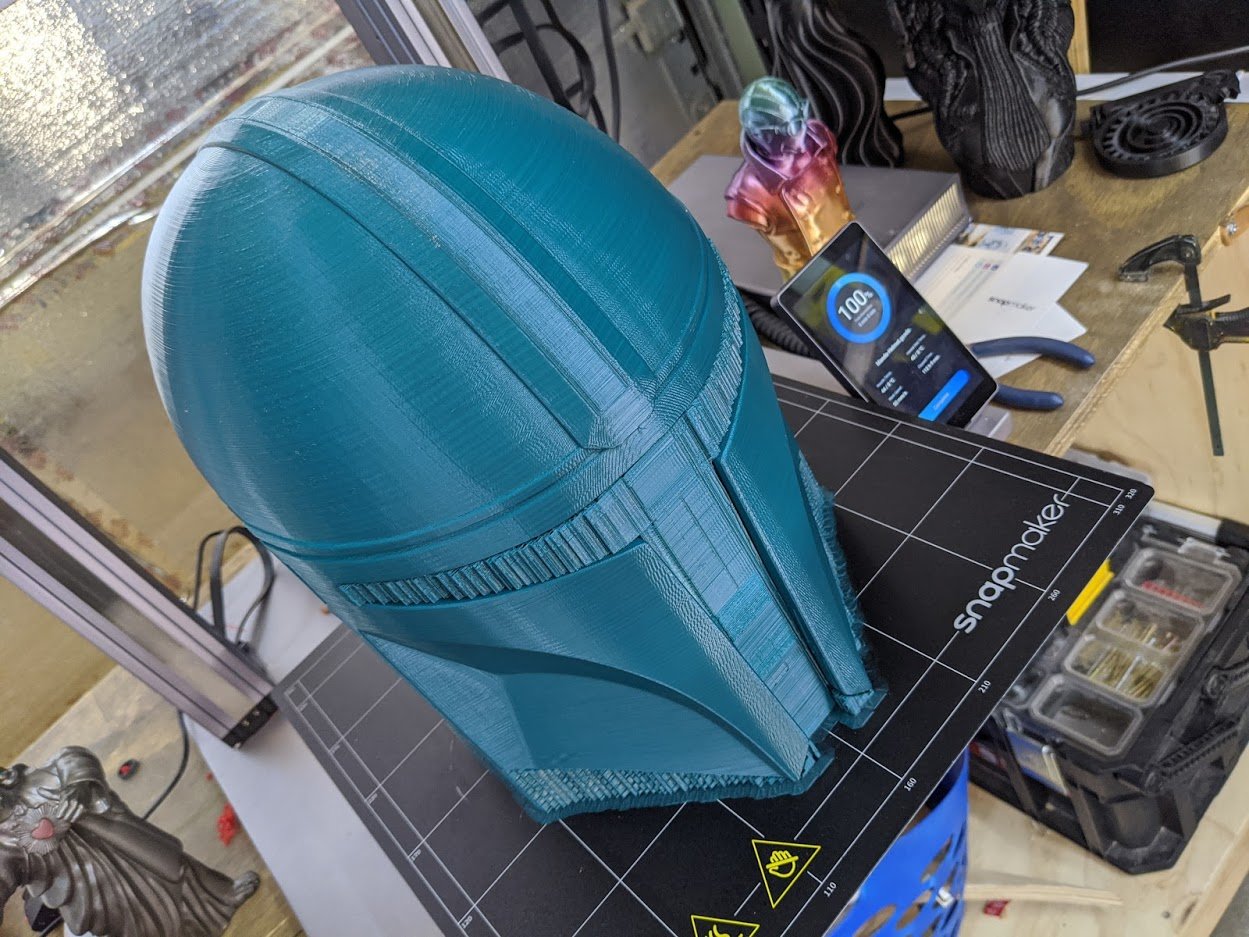

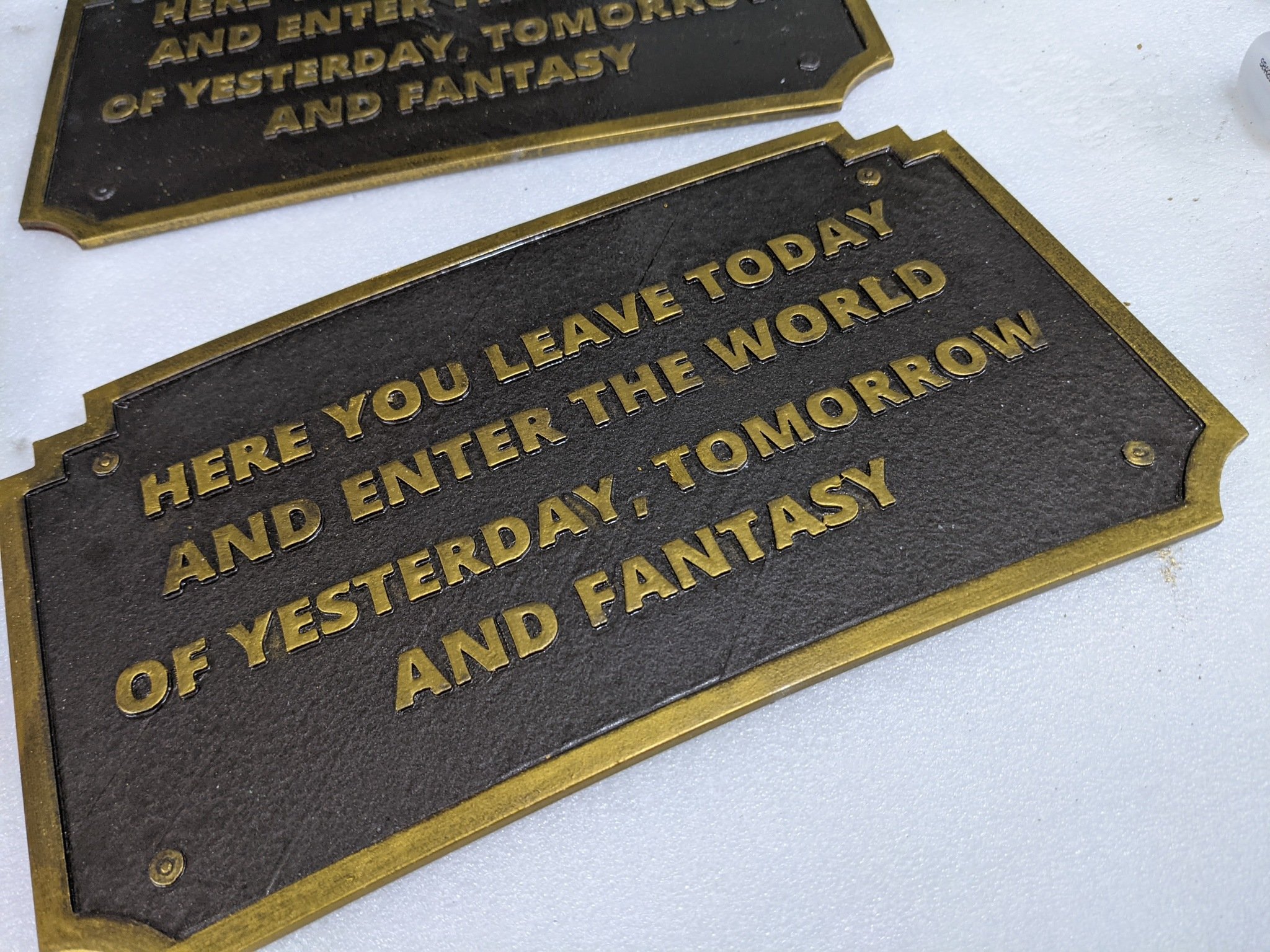

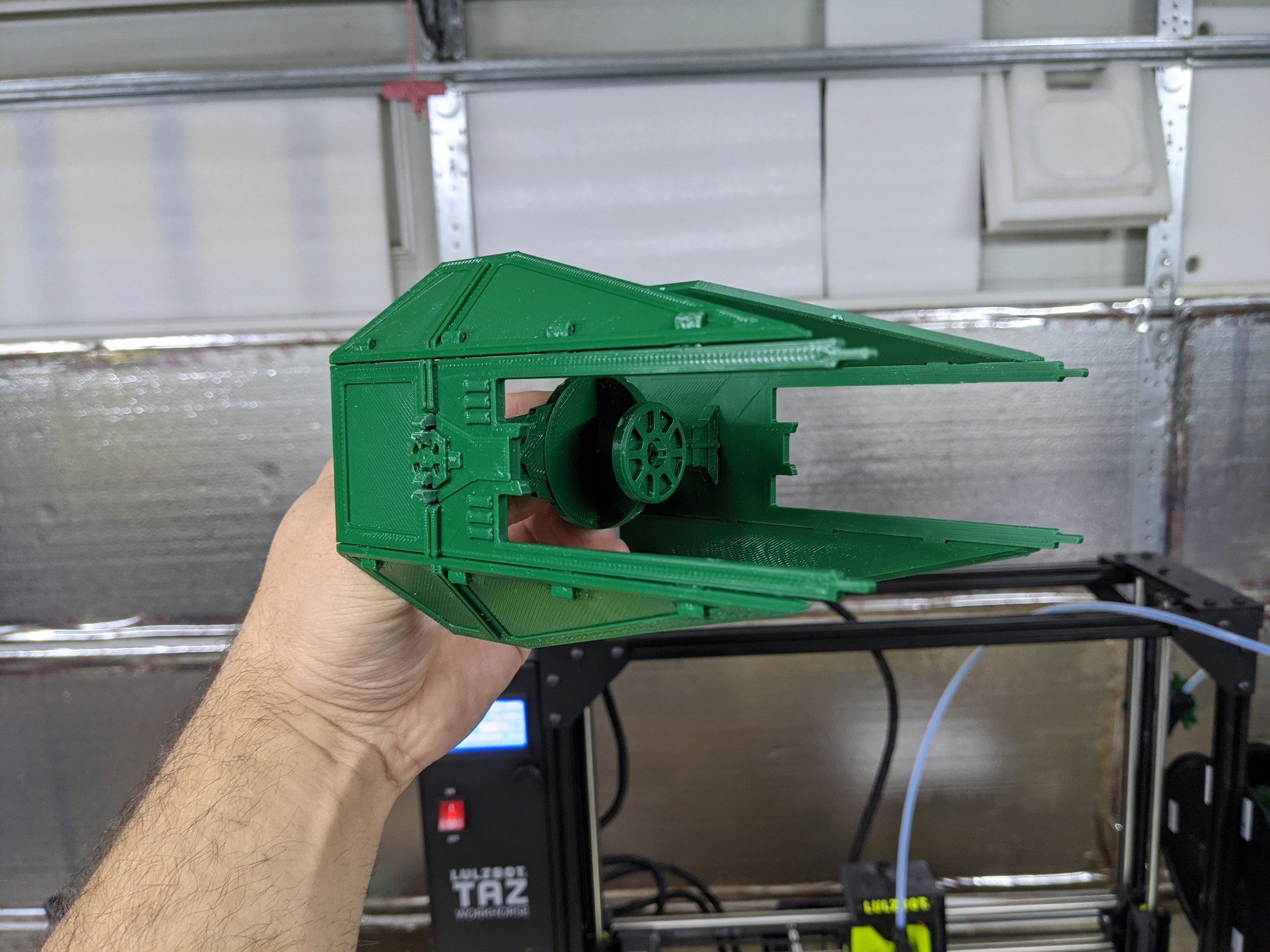

We've spent hundreds of hours printing on this Workhorse, creating fun models, cosplay props, and practical prints to upgrade other printers, and each one printed out very well, except for that all-important first layer. We'll dive deeper into that later, but the issues we had are almost a deal-breaker for me.

Bottom line: I wanted the TAZ Workhorse to be exceptional, and it nearly is. A new leveling system would be a gold standard; without it, it's just good.

Pros

- The bed size is great for large work

- Swappable tool heads can expand your horizons

- Excellent quality when it works

Cons

- The auto bed leveling is shockingly poor

- The cost is still very high

LulzBot TAZ Workhorse: Price and availability

The TAZ Workhorse is at the cusp of hobbyist and commercial 3D printers. At around $3,000, the price is very steep for someone just getting started in the hobby, but not so bad for a business looking for longevity from their printers. LulzBot is known for its great customer service, and the printers last a long time, so the $3,000 is an investment.

MatterHackers is the best place to buy the LulzBot right now, as the price is good, the printer is always in stock, the support from MatterHackers is excellent, and there are extra bundles you can purchase to increase the bang for your buck.

LulzBot TAZ Workhorse: What's good

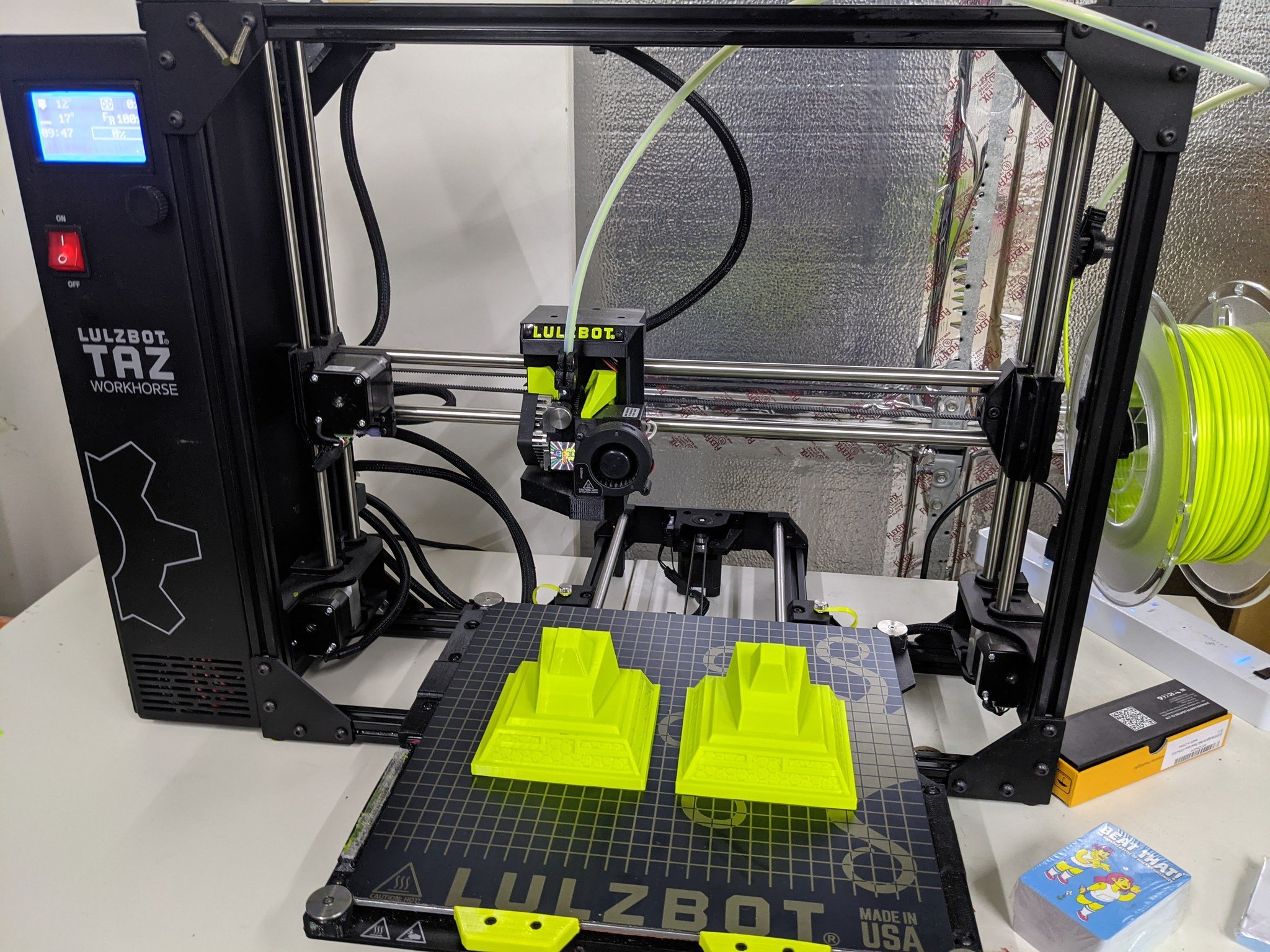

The first thing you will notice when you unbox the TAZ Workhorse is the size of both the printer and the print area. While the print size is a respectable 280mm x 280mm x 285mm, the printer itself has a footprint of 832mm x 662mm, so you will need to make sure you can accommodate that in your workspace. The print size is big enough to make a lot of practical prints that you may not be able to fit in a standard printer. Even our best 3D printers don't have a bed as big as the Workhorse.

LulzBot does offer a variety of extra tool heads that elevate your TAZ Workhorse, making it anything you want it to be.

The standard workhorse comes with a 0.5mm tool head that uses 2.85mm filament, and while the 0.5mm nozzle is excellent for large and practical prints, the 2.85mm filament is a little outdated. Most 3D printers have switched over to the 1.75mm filament that is far easier to find. If you own other printers, you'll need to keep the size change in mind, as you likely won't be able to use the filament you already have. Happily, though, LulzBot does offer a variety of extra tool heads that elevate your TAZ Workhorse, making it anything you want it to be.

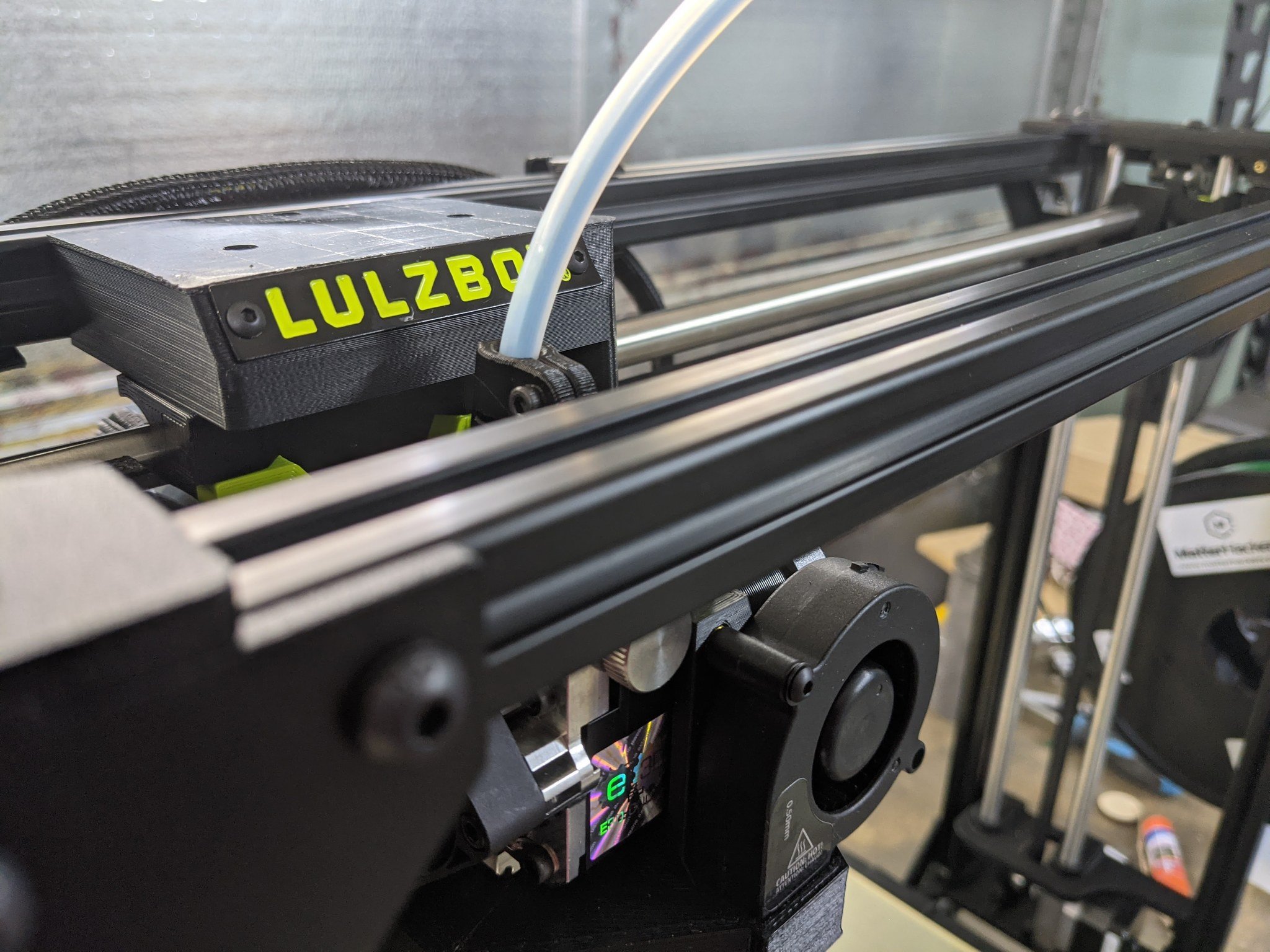

I got to try out the H175 tool head that let me use the 1.75mm filament, and it was a dream. In fact, LulzBot should really offer the Workhorse with a 1.75mm tool like the H175; it makes everyday printing a breeze. The Hemera hotend worked so well, and as you can see on the scope for the cosplay rifle in the gallery, it prints like butter. It would be perfect as the standard printhead for the Workhorse.

All the latest news, reviews, and guides for Windows and Xbox diehards.

There are tool heads to make the Workhorse a dual extrusion printer — it lets you use two different materials simultaneously and ones with hardened steel nozzles for working with abrasive filaments like carbon fiber. All the tool heads can be swapped easily now that the firmware has been updated with a tool head picker on the printer interface. It's all simple to do and adds a lot of variety to your machine.

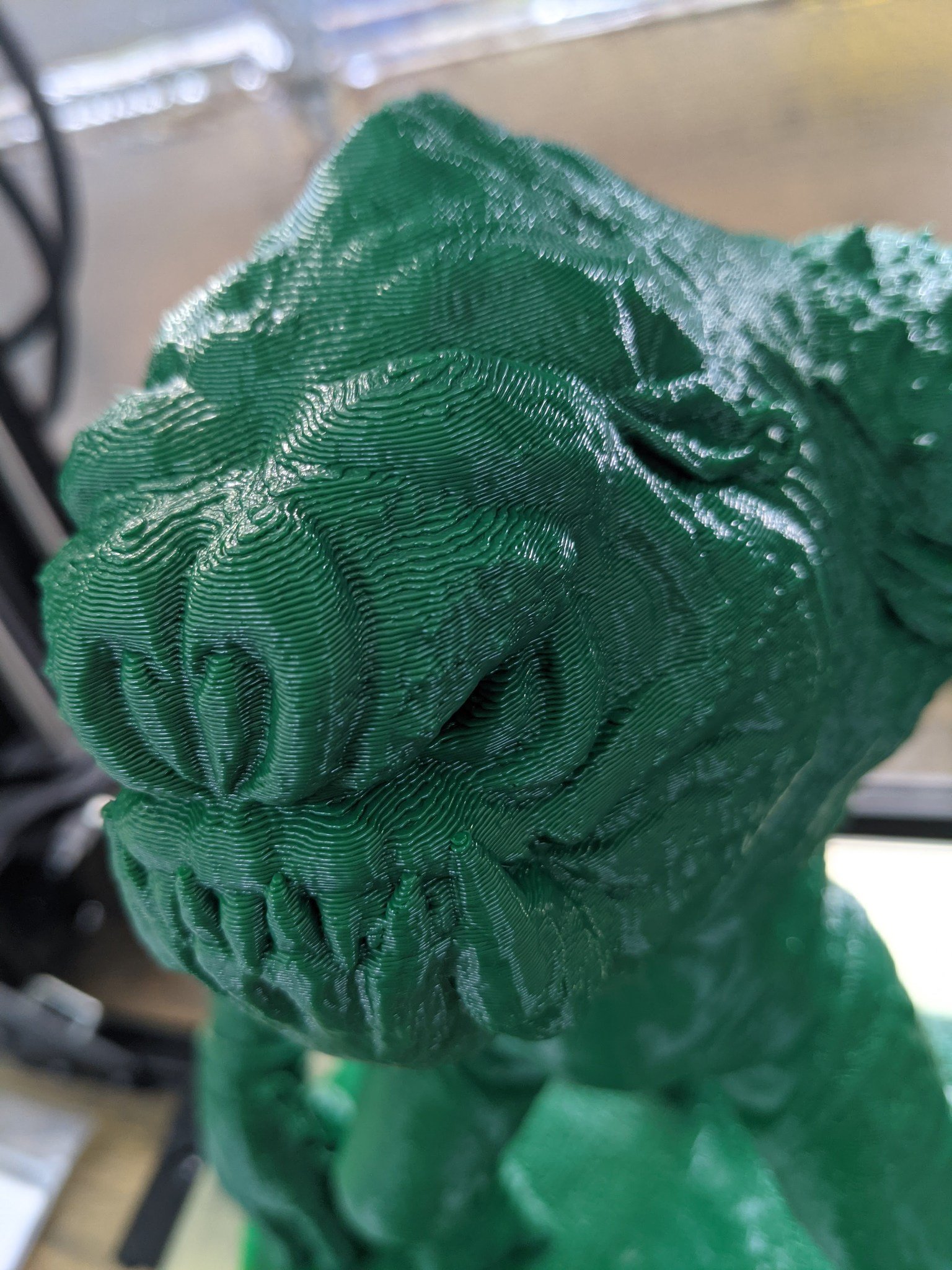

One of my favorite prints on the Workhorse so far is the set of rollers I made for the Creality CR30 belt printer. Not only did the print come out perfectly, but the dimensional accuracy was exactly right. The rollers required me to push-fit bearings into the ends of the rollers, and the LulzBot printed the holes exactly right for a snug fit. If you look at the layer lines on the Rancor nose from ChaosCoreTech, you can see how even the layer lines are and well they are fused. That model was printed at 0.4mm layer height — something I rarely do for sculptures — and the layer lines add to the model rather than detract.

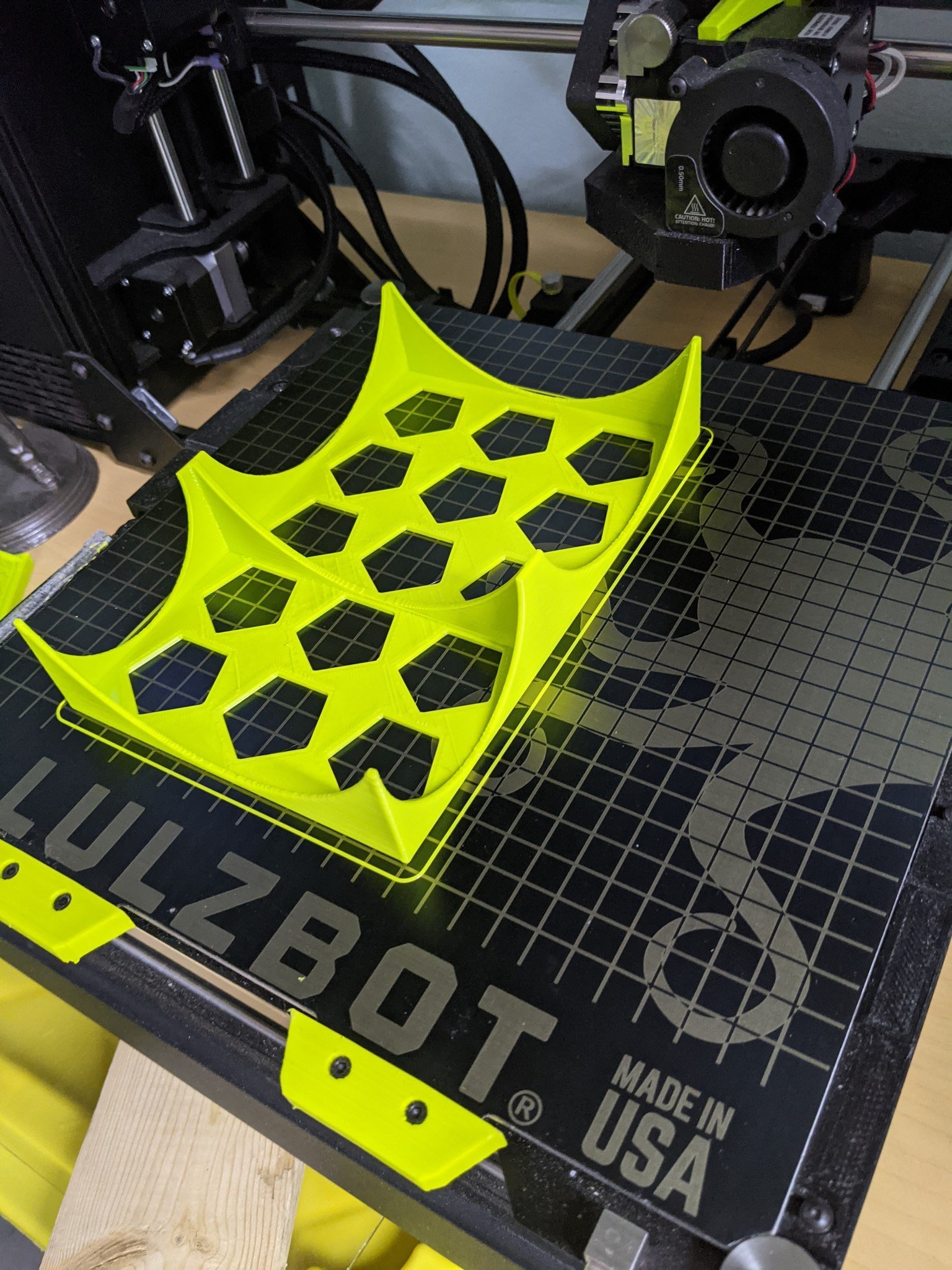

Practical prints are definitely the TAZ Workhorse's strong suit. The big nozzle and sturdy frame give you excellent results when making models designed to last. I designed and printed a stand for my wife's macarons, and because of the thick layer height and great print quality, they came out great. The biggest problem, though, is when you make those flat, long models. The TAZ Workhorse has a bed leveling problem, and it makes me want to scream.

LulzBot TAZ Workhorse: What needs work

My biggest complaint with the Workhorse is a big one, and though my specific machine seemed to suffer from it more than others, I have had reports that others have the same problem. The bed leveling system on the Workhorse is disappointing, flawed, and without any practical way to fix issues. Most modern printers like the Prusa Mk3 come with an auto bed leveling system that uses a mesh of magnets and a probe to measure your print bed accurately and then dynamically alter the nozzle depending on the deflection your print bed is suffering from. No print bed is truly flat, as the metal can distort under heat, but a mesh leveling system will allow your first layer to print smoothly regardless.

The TAZ Workhorse has a bed leveling problem, and it makes me want to scream.

The TAZ Workhorse uses the same probe system that LulzBot has used for years, and while it was good for the time, it has failed to keep up with the changing times. The Workhorse uses four metal discs at each corner to measure the entire bed, and it fails to level it more times than it succeeds. In fact, to get the bottom layer to succeed on some of my larger prints, I had to manually adjust the Z offset while the print was running to get it to lay down correctly. The difference is so large in some places that the nozzle would crash into the PEI sheet on one side and then print in the air on the other.

With the way the Workhorse levels, there is simply no way to manually correct it if it doesn't work, which is a big problem. It's either all or nothing, with only software fixes available. I would like to see LulzBot work on a new bed leveling system as they look to the future. When you are making premium machines that cost big money, having an uneven bed is simply not ok. My Anycubic Vyper has a better bed leveling system and is a small fraction of the price. Not a good look.

LulzBot TAZ Workhorse: Competition

The sheer print volume of the LulzBot is the main draw, and there are plenty of large-scale printers out there for a lower cost than you could use. I would opt for something like the Snapmaker 2.0 as it has a great 3D-printing module but also allows you to laser cut and CNC mill with equal ease. It's a home manufacturing system, not just a printer.

The Creality Ender 5 Plus would be a good deal for a dedicated, large-scale printer, especially as you could buy four of them and still have money left over for upgrades. They may not run as well as the Workhorse out of the box, but they would eventually, and you would have four times as many printers.

LulzBot TAZ Workhorse: Should you buy it?

You should buy this if ...

- You want a large build area

- You want to use different tool heads

- You need something that will print forever

You shouldn't buy this if ...

- You are on a tight budget

- You are low on space

- You want mesh leveling

Buying the Workhorse is not going to be an impulse buy. It's a big purchase for a company, and you need to make sure you are ready for it. If you are a small business with a dedicated workshop, then the Workhorse is a great investment. However, if you are a hobbyist with a small footprint and less than perfect surroundings, you may want to think about something smaller.

I really want to love the TAZ Workhorse and recommend it to all, but the issues with the bed leveling have made that difficult. It seems that my machine suffers from this issue more than others, but I can only go off the product I've used. Until they come up with a better system, I would be wary of buying such a high-priced product. You will need to have the best possible conditions and be prepared to spend time tweaking to get that first layer to lay down perfectly.

As a small business, though, having changeable tool heads can't be overlooked, and the bed size and overall sturdiness of the printer are big pluses too. Having a printer that can be as versatile as your products is no small thing for any business.

James is a Former Contributor who built his first PC when he was 13 and has never looked back. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games.